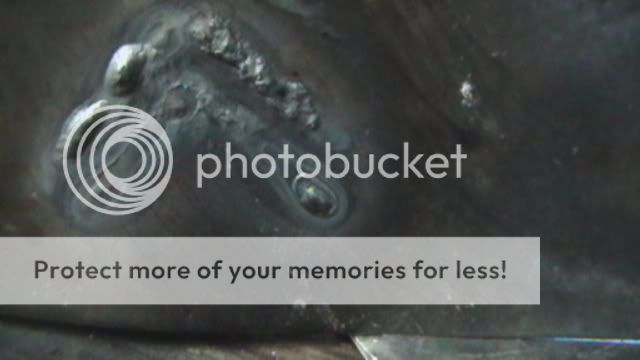

TIG welding on metal that hasn't been cleaned to bright metal (i.e SPOTLESSLY clean) is a huge waste of time. You'll never have a sound weld, and you'll contaminate the tungsten unbelievably. The steel weld needs to be cleaned, but you either have too much heat in it, or you're moving too slowly on your travel speed. Typically, when you can make out the HAZ or see a little bit of the scale flaking off on the underside of a mild steel weld, you've got the right heat/travel speed. Any burn through at all is too much.

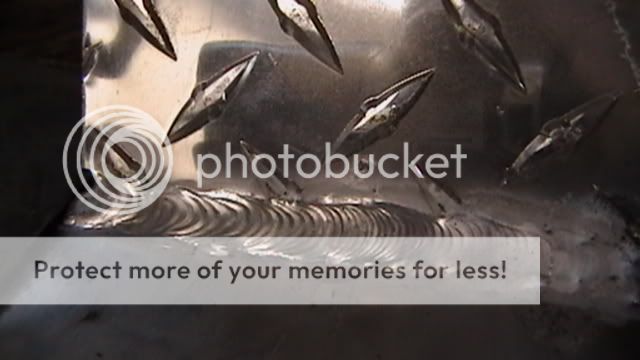

Good start with the aluminum. Over time, people will gradually go from what I call panic mode, which is "oh God, the arc is on, throw filler in there now!", to having complete control over the puddle, the way the filler wets out, bead spacing, timing, etc. It takes a LOT of practice, but it's as though time slows down when you get good at it.